Project Overview

| Customer | Boehringer Ingelheim |

| Sector | Mass timber – energy industry |

| Location | Ingelheim am Rhein, Germany |

| Solution | segus Negative Pressure System |

| Filter | EtaMax Impulse filter |

| Extraction Capacity | 75.000 and 15.000 m³/h |

| Special Features | – high reliability and fault tolerance – exceptionally quiet due to sound insulation measures |

| Commissioning | 2024 |

High reliability and fault tolerance

A contribution to the supply security of patients.

Scheuch LIGNO installed an extraction system with a capacity of 75,000 m³/h for the new biomass combined heat and power plant of Boehringer Ingelheim, a leading pharmaceutical company in Germany. The EtaMax impulse filter, featuring six integrated fans, impressed the client with its high reliability and fault tolerance.

Since summer 2024, the new biomass power plant has been supplying the Ingelheim site with green electricity and steam. It is one of the most environmentally friendly power plants in Rhineland-Palatinate and makes a significant contribution to Boehringer Ingelheim’s climate targets. Annual CO2 savings are expected to reach 50,000 tonnes. “The biomass combined heat and power plant ensures the energy supply for the site and thus significantly contributes to Boehringer Ingelheim’s reliability in providing patients with essential medicines,” explains Frank Zornow, project manager at Boehringer Ingelheim.

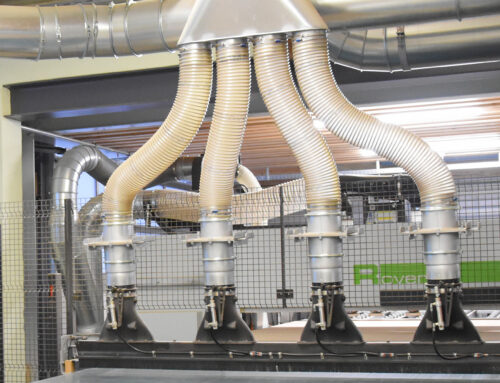

Required Air Volume Maintained Even with Fan Failure

Scheuch LIGNO was awarded the contract for the dust extraction system at the biomass combined heat and power plant. The Austrian air technology specialist impressed Boehringer Ingelheim’s project team with its EtaMax solution. This impulse filter is equipped with six integrated fans, ensuring that even in the event of a fan failure, the required air volume of 75,000 m³/h is still maintained. “Our requirements for the extraction system were that it needed to be efficient, reliable, quiet, and economical. Scheuch LIGNO has an excellent reputation in the market and stood out in the competition with its combination of quality and price,” emphasises Frank Zornow. “The collaboration with Scheuch LIGNO was very good, efficient, and always goal-oriented. I can recommend the company at any time.”

An Additional Radial Fan as Performance Reserve

For daytime operation, this extraction solution runs five radial fans on the clean gas side of the filter system, providing a total air volume of 75,000 m³/h. During night-time operation, one of these fans is used, with its extraction air volume reduced to 7,000 m³/h via a frequency converter. An additional radial fan with a total air volume of 15,000 m³/h has been installed in the filter system as a performance reserve. The material separated in the filter is discharged via a screw conveyor through a rotary valve. Using a diverter valve, the material is directed onto one of two conveyor belts and subsequently transported to the boiler house.

Low Noise Emissions Thanks to Insulation and Silencers

To minimise noise emissions, the extraction system is fully insulated with 100 mm of cladding. Additionally, pipe silencers have been installed on the raw gas inlet side, and louvre silencers are used on the discharge side of the EtaMax filter.

Comprehensive Know-how

Building on the high industrial standard of ligno large-scale filter systems, Scheuch LIGNO offers the ligno impulse filter series for performance ranges between 20,000 and 400,000 m³/h. This showcases the company’s comprehensive expertise in filtration and dust extraction technology. The impulse cleaning system from Scheuch LIGNO excels with its energy efficiency, operational reliability, and fire and explosion protection concept. Energy savings are further supported by the low-pressure drop of the integrated impulse filter and the high efficiency of the built-in fans (EtaMax unit).

„Our requirements for the extraction system were that it be efficient, reliable, quiet, and economical. Scheuch LIGNO has an excellent reputation in the market and succeeded in the competition with its combination of quality and price. “