Medium-pressure conveying systems

For long distances with high discharge rates

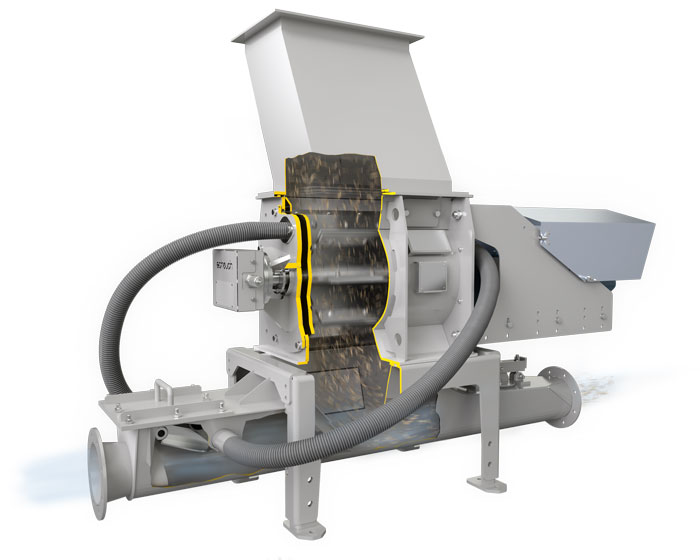

Inward material transfer with T-injector – the key components at a glance

If materials need to be conveyed over long distances and/or in large quantities, medium-pressure conveying systems (MP conveying systems) are a cost-effective choice. They involve indirect transport – the blower is positioned upstream of the material feed unit.

The key components of an MP conveying system are the rotary piston blower, which is highly efficient but keeps energy costs to a minimum, the material feed unit with a very robust rotary valve and a T-injector for effective material acceleration as well as the flow-optimized pipe system.

Thick-walled steel pipes and special bends with wear protection and a large bend radius ensure long service lifetimes and high operational safety.

Flow-optimised material feed into the conveyor pipe is crucial for a high loading rate.