Pre-treatment

Pre-treatment is the basis of a high quality coating process. Removing dirt and substances goes hand in hand with continuous system conceptual design. Scheuch LIGNO examines all production processes thoroughly to find the best pre-treatment method to combine with further processing. The coating process therefore a;ready begins during the production process and requires a coherent interconnection with the coating system. Scheuch LIGNO has the right solution for you, whether it’s in the form of a washing booth, phosphate coating, a scraping and grinding booth or a grinding table.

The solutions at a glance:

Grinding booths

The Scheuch LIGNO grinding booths can be used in modules. This individual module design enables booth sizes to be adapted to the customers’ wishes.

Scheuch LIGNO grinding booths with recirculated air operation are easy to operate and service, and boast an attractive design. Highly efficient cartridge filters with a patented › Scheuch impulse cleaning system, plus a fan and control components are integrated into the booths. The supply air ceiling ensures targeted guidance of the air flow in the booth and employee area. The TOP-DOWN effect moves the dust-laden air efficiently to the extraction openings. Recessed ceiling lights guarantee ideal conditions at the workstation. The Scheuch LIGNO Powerbox controls the system and the lighting, and supplies the grinding booth with compressed air and power. Extraction connections for mobile grinding devices can also be connected to the Powerbox.

Scheuch LIGNO overhead grinding booth

Overhead grinding booths are ideal as additional extraction units to go alongside the device’s own extraction function for manual grinding work with hand-held grinders and for work with manually operated grinding machines.

The dust is extracted on the ground in the longitudinal direction. The measured values prove that even blasting the workpieces does not cause a high dust load for the employees. It is therefore possible to blast the workpieces and clean the booth using a Scheuch LIGNO system. A sophisticated air supply system on the ceiling keeps the dust on the ground. A simple drawer system enables the dust to be disposed of quickly. A grinding booth reduces dust and noise considerably.

Scheuch LIGNO overhead grinding booth

Overhead grinding booths are ideal as additional extraction units to go alongside the device’s own extraction function for manual grinding work with hand-held grinders and for work with manually operated grinding machines.

The dust is extracted on the ground in the longitudinal direction. The measured values prove that even blasting the workpieces does not cause a high dust load for the employees. It is therefore possible to blast the workpieces and clean the booth using a Scheuch LIGNO system. A sophisticated air supply system on the ceiling keeps the dust on the ground. A simple drawer system enables the dust to be disposed of quickly. A grinding booth reduces dust and noise considerably.

Scheuch LIGNO underfloor grinding booth

On underfloor grinding booths, extraction takes place via a floor pit. They are used as additional extraction units to go alongside the device’s own extraction function for manual grinding work with hand-held grinders and for work with manually operated grinding machines. Furthermore, they reduce dust and noise.

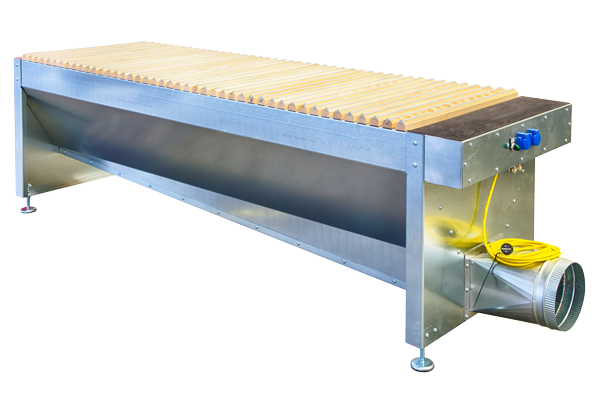

Grinding tables

Grinding tables are used as additional extraction units to go alongside the device’s own extraction function for manual grinding work with hand-held grinders and for work with manually operated grinding machines. The grinding table reduces dust considerably. If the grinding table has a work surface which can be pivoted infinitely, this will make it even more functional and ergonomic. The ability to adapt the workpiece inclination to the grinding processes in question (surface, transverse edges or longitudinal edges) makes the grinding work much easier. Pressing a button releases the pneumatic lock and the grating can be swung into the position required for processing manually.

Optimum extraction when processing edges is ensured by the gap between the table base frame and the swivelling upper part.

Blasting cabins

Scheuch LIGNO provides blasting rooms and blasting booths that are adapted to the customer’s requirements. The materials are conveyed via conveyor floors driven by pneumatic cylinders. The booth designs with heavy goods vehicles for material transport or tracks to enable forklifts to move are adapted to the customer’s requirements. The blasting agent reprocessing and recovery are fully automated. The filter technology and the extraction systems are state of the art in order to protect employees and the environment. The blasting room designs can be configured individually – with a ceiling slot to use the hall crane for filling or to enable access by forklifts. Hoists to handle the components to be blasted can also be integrated.