Project Overview

| Customer | Schilliger Holz |

| Sector | Mass Timber |

| Location | Volgelsheim, France |

| Solution | segas+ negative pressure system |

| Filter | impulse filter |

| Extraction Capacity | 140,000 + 180,000 m³/h |

| Special features | filter update |

| Commissioning | 2006 + 2023 |

Long-lasting extraction system at Schilliger Holz

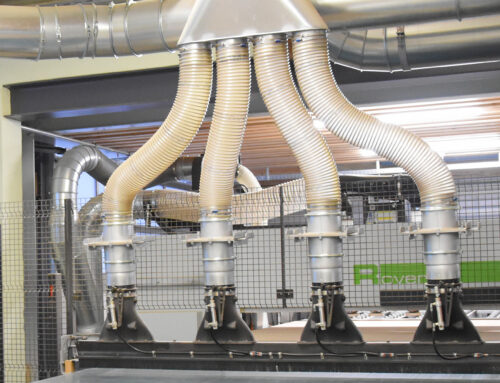

The segas+ extraction system from Scheuch LIGNO at Schilliger Holz’s site in Volgelsheim, France, stands out for its durability, outstanding quality and energy efficiency. A filter unit with a capacity of 140,000 m³/h, which has been operating to the full satisfaction of the Swiss company for almost two decades, was brought up to the latest technical standard by the Austrian extraction specialist and will now ensure optimum extraction performance for many more decades in the new CLT production facility. As part of the conversion, an additional filter system with an extraction capacity of 180,000 m³/h was installed for the former glulam production hall, along with more than 1,035 metres of ductwork.

A system built for the future – with maximum availability

The extraction system from Scheuch LIGNO impresses not only with its outstanding quality and long service life, but – with a total extraction capacity of 320,000 m³/h – also represents a future-proof investment for Schilliger Holz thanks to its forward-looking design. “We’ve already planned for additional machines that haven’t yet been ordered but have been taken into account in the system design. This means the extraction system is clearly equipped to meet future demands,” says Managing Director Ernest Schilliger.

Significant potential for energy savings

In a modern CLT production facility, extraction accounts for around one third of total electricity consumption – meaning the potential for energy savings is considerable. To keep energy usage as low as possible, Scheuch LIGNO assigns a fan tailored precisely to each machine group in the segas+ extraction system. This fan delivers the exact volume flow–pressure ratio required at any given time. Unlike vacuum systems, which can only generate a single negative pressure, this setup allows for customised performance for each duct line. The precise coordination of all components results in excellent energy efficiency. In Volgelsheim, fans with a combined output of 826 kW were installed.

Vacuum control with raw-gas-side fan arrangement

Until now, vacuum control has typically only been used in vacuum systems. Scheuch LIGNO has now successfully implemented vacuum control in group extraction systems with fans arranged on the raw gas side. The vacuum required at the machine remains constant at a steady extraction speed. This pressure is measured and adjusted as needed via a frequency converter. As a result, the extraction performance remains consistent and always within the optimal range throughout the entire filter service life. The common problem of vacuum systems, where a single system pressure is used for all extraction groups, is now a thing of the past. Each extraction group can be individually configured in terms of airflow and pressure increase – ensuring energy is used as efficiently as possible.

Schilliger Holz AG – Expertise and innovation since 1861

In addition to sawmills at its three locations in Haltikon (CH), Perlen (CH) and Volgelsheim (FR), Schilliger Holz AG operates planing mills, glulam production facilities, panel plants for solid wood and large-format panels (GFP/CLT), drying systems and a pressure impregnation plant. A fibreboard plant is also currently under construction. Highly qualified employees and specialists in the fields of engineered timber construction, timber construction, surface technology, production and logistics are ready to take on a wide range of challenges.

Find out more at www.schilliger.ch.

„The fact that the old system has been running for so many years and is now continuing in operation after being modernised speaks volumes for its quality. That’s why we’ve already planned to use Scheuch systems again in a new project.“