Pellet Production

Dedusting in the entire production process – specific equipment to prevent moist air

In pellet production, there are various requirements for dedusting the systems. Scheuch LIGNO conveyor systems have proven their worth when supplying chips. Further chip conveyance within the system is normally completed mechanically. The Scheuch LIGNO technology is used again at the transition points and ensures that the air is clean. The conveyance routes are dedusted here. In your own filter system or in a collective filter system depending on the system size.

The pellets are produced in the next production step and stored intermediately in the cooler. This releases warm, damp air. Scheuch LIGNO has gathered many years of experience in this area and can equip the filter system specifically to withstand the influences of very moist air and the substances dissolved in it, which are normally corrosive. Finally, the finished pellets are dedusted before loading. Dedusting also takes place during the loading process.

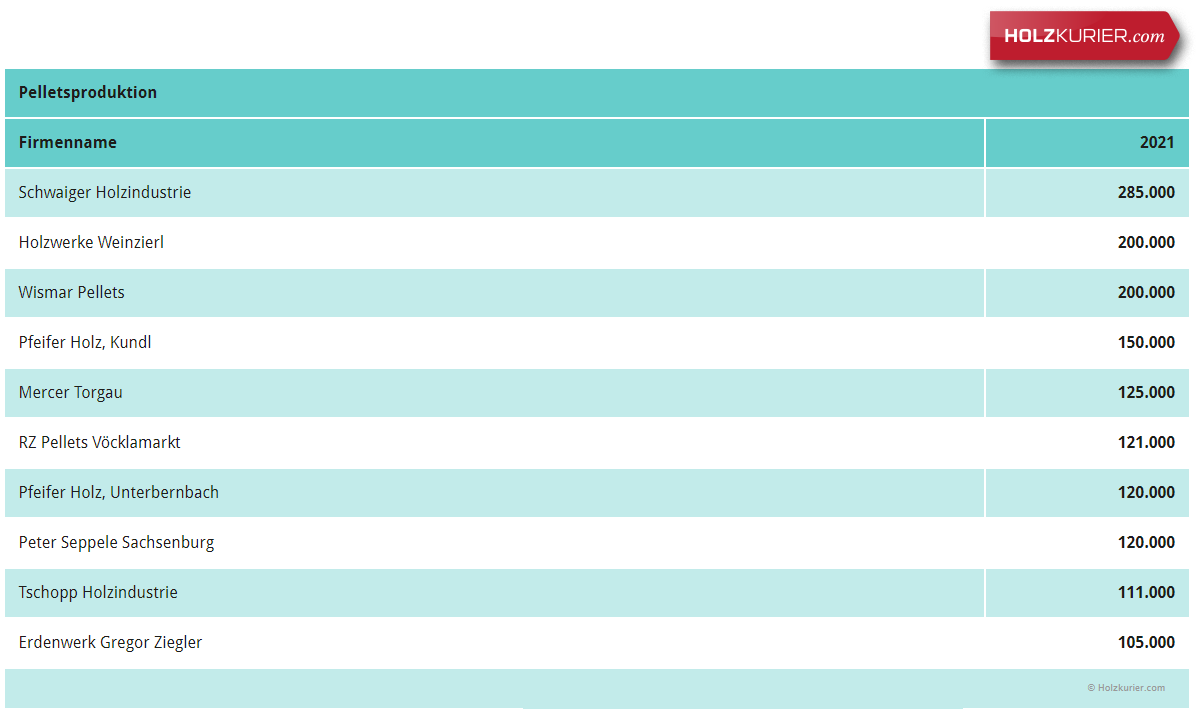

The largest pellet producers in the German-speaking countries, which are also the top 10 customers of Scheuch LIGNO in this area:

Quelle: Holzkurierf magazine

The largest pellet producers in the German-speaking countries, which are also the top 10 customers of Scheuch LIGNO in this area:

Quelle: Holzkurier magazine

Your customized solution is just one step away!

With our extensive experience, we are your reliable partner for extraction and surface technologies in industry and trade. Guided by our commitment to providing „the most economical solution for trade and industry,“ we work together to achieve the best results tailored to your needs. Simply enter your contact details, and we’ll get back to you as soon as possible.