Services

Technical customer service hotline:

Service with quality

Scheuch LIGNO has established itself as a high-quality manufacturer and provides a complete range of products and services. Reliability and adherence to deadlines characterise our operating principle. The employees are in the field around the world and concentrate on installing and commissioning of Scheuch LIGNO systems.

Technical customer service hotline:

Your contact person

Service manager

Florian Brandstätter

Tel.: +43 7752 905-8593

Mobile: +43 664 8116785

E-mail: F.Brandstaetter@scheuch.com

Assembly team leader

Mersad Muranovic

Tel.: +43 775 2905-8420

Mobile: +43 664 8116965

E-mail: M.Muranovic@scheuch.com

Customer service & after sales team leader

Jürgen Sallaberger

Tel.: +43 775 2905-8622

Mobile: +43 664 88110062

E-mail: J.Sallaberger@scheuch.com

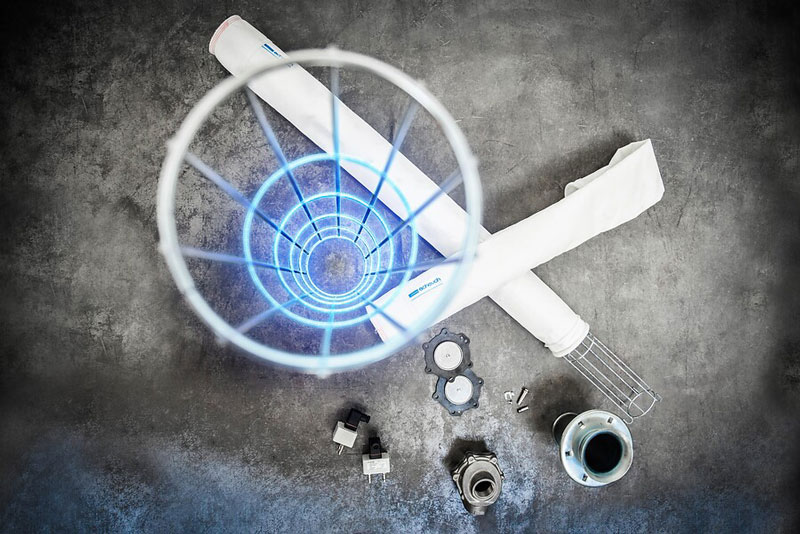

Spare parts

Assembly

Distinguished assembly and commissioning expertise

Our in-house assembly and commissioning department is what sets us apart. Around 40 people currently work here.

The Scheuch LIGNO assembly department boasts extensive product and process expertise thanks to its staff members’ continual presence on various construction sites around the world and the fact that their work focuses exclusively on installing and assembling components and systems for air pollution control.

Commissioning

Ensuring operational safety for the future is the key

Operational safety is our highest priority. Numerous checks guarantee unsurpassed safety. The system is set to offer optimum performance in line with the individual operating conditions during a test run. Individual fine-tuning measurements are used to ensure agreed performance guarantees with regard to air volume, equipment, sound pressure level, etc.

Professional customer training sessions enable the system to be used and operated independently. The benefit of this for the customer is that it also gives them the skills they need to perform periodic cleaning and maintenance work independently in the future.

Round-the-clock system availability

Remote monitoring is recommended in cases where plants must be available around the clock. Remote data transmission makes it possible to perform ongoing diagnostics relating to the system status. Sensors and visualisation equipment that are appropriate for the task in question display system-specific process parameters and functions, therefore allowing us to initiate optimisation measures at any time. This keeps faults to a minimum and largely prevents shutdowns. The risk of production downtimes is also minimised.

Maintenance & system check

We provide:

During the annual system check, Scheuch LIGNO assesses the current state of your system compared to the date of construction, as a regular inspection is extremely important. As a third party with a profound knowledge of your processes and with our many years of experience, we are in an ideal position to maintain an unbiased view.

Maintenance – for long-lasting run times

Maintaining your system regularly ensures many years of efficient and optimum system performance. Our scheduled maintenance work includes checking the condition and quantity of lubricants and additives, as well as refilling, changing and cleaning them. On filter systems, this mainly affects the units that generate the gas flow (e.g. motors and fans) and components for providing compressed air, such as compressors and dryers.

An inspection and maintenance contract includes regular checks of your system with the necessary adjustments and maintenance work, of course.

Spare parts

If something does need to be replaced, we are always on hand with spare parts for our system components. We keep all current spare parts in stock. This means that damage can be repaired as quickly as possible, keeping your systems up and running, and ensuring your production processes aren’t interrupted. That’s a guarantee.