Conveying

technology

The heart of every system

The conveying system is a key component of every chip extraction system and has a significant impact on the operational safety and availability of the overall production system. The conveying technology can be regarded as the lifeline of the system and guarantees fault-free operation, particularly in the event of complex, interlinked production units.

Scheuch LIGNO has always been known for its reliable conveying systems. An uncompromising focus on power and availability is one of the foundations of our company philosophy. Pneumatic conveying systems convey material such as swarf, chips, dust or pellets from the feeding point to a storage facility or separation system. At the feeding point, a rotary valve (pressure barrier and protective system) feeds the conveyed material into the conveying air flow which carries it through the conveyor pipe.

Low-pressure or medium-pressure conveying systems are used depending on the project requirements, the type and quantity of material and the conveying distance. Low-pressure systems are designed with direct or indirect fan placement, depending on whether the fan is positioned upstream or downstream of the feeding point. They are available both with and without a closed circular pipeline.

Scheuch LIGNO’s comprehensive expertise in conveying technology guarantees that we are able to select the most efficient solution for every application.

Two basic systems for material conveyance

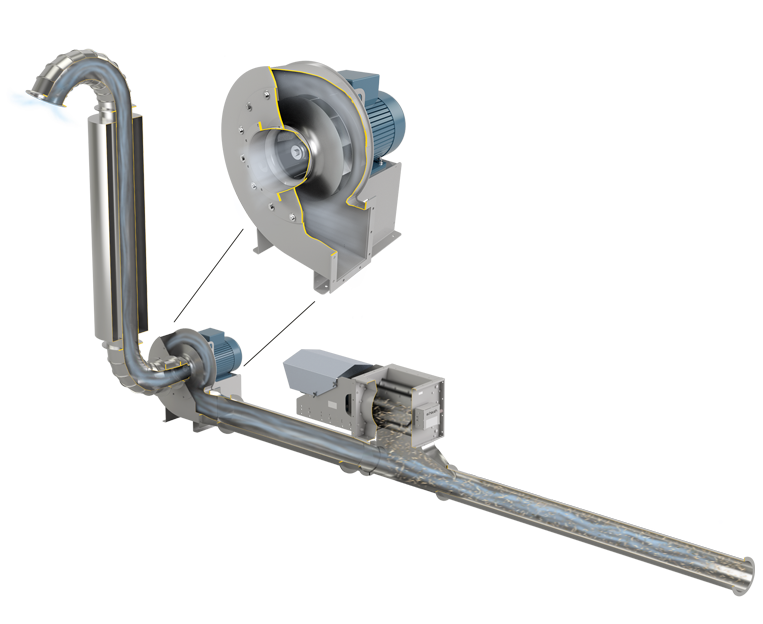

Direct conveyance – the conveying fan is positioned downstream of the material feed unit

The conveying fan is positioned downstream of the material feed unit. The material is conveyed directly via the radial fan. The air flow sucks the material under the rotary valve and into the conveying system.

Wear-resistant steels or special materials are used for the open impeller. Additional wear protection for the casing ensures high stability. Depending on the conveying capacity, radial fans with belt drives may also be used. The pressures in the duct are distributed evenly.

The conveyed material flows through the radial fan, which means that it experiences increased mechanical stress and in most cases changes its consistency. The bulk density may be higher.

Indirect conveyance – the conveying fan is positioned upstream of the material feed unit

The conveying fan is positioned upstream of the material feed unit, which means that transport takes place indirectly with the air flow accelerating the conveyed material under the rotary valve. There is no wear on the fan impeller. There is also no possibility of sparks being caused by foreign objects.

The material is only conveyed through the duct, it experiences little mechanical stress and thus remains in its original consistency. The delivery pressure at the material feed unit is high, the leakage air at the rotary valve increases and downstream components are under high pressure. The bulk density remains roughly the same.

Your customized solution is just one step away!

With our extensive experience, we are your reliable partner for extraction and surface technologies in industry and trade. Guided by our commitment to providing „the most economical solution for trade and industry,“ we work together to achieve the best results tailored to your needs. Simply enter your contact details, and we’ll get back to you as soon as possible.