Low pressure conveying systems

Safe and efficient over any distance

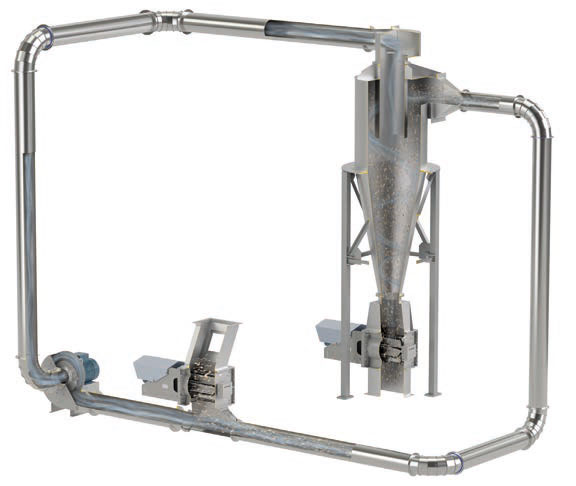

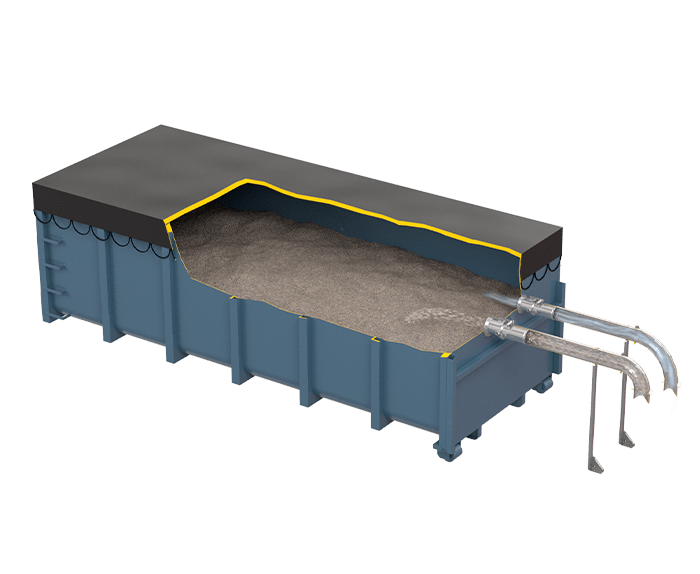

Closed circular pipeline conveyor system

The material is transported using a closed circular pipeline conveyor system.

The radial fan blows the separated material in the conveyor pipe towards the material separator.

The recycled air is fed back towards the radial fan. With this type of conveyance, the air is guided in a circular motion, which means that no dust is discharged.

Broschure

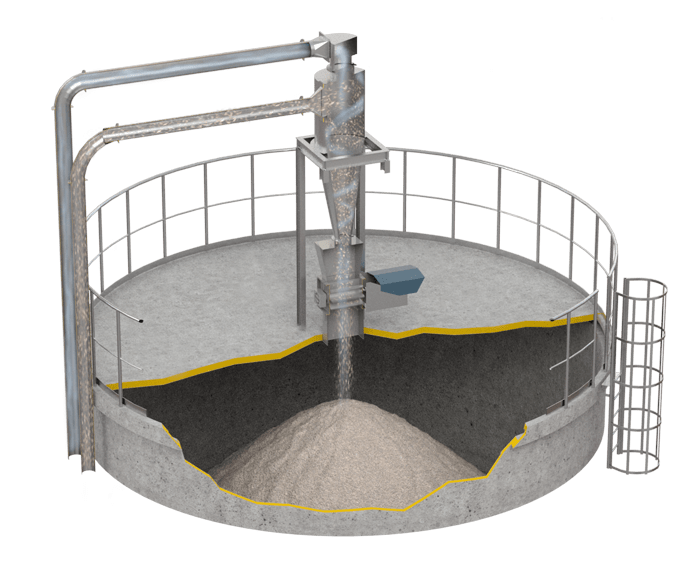

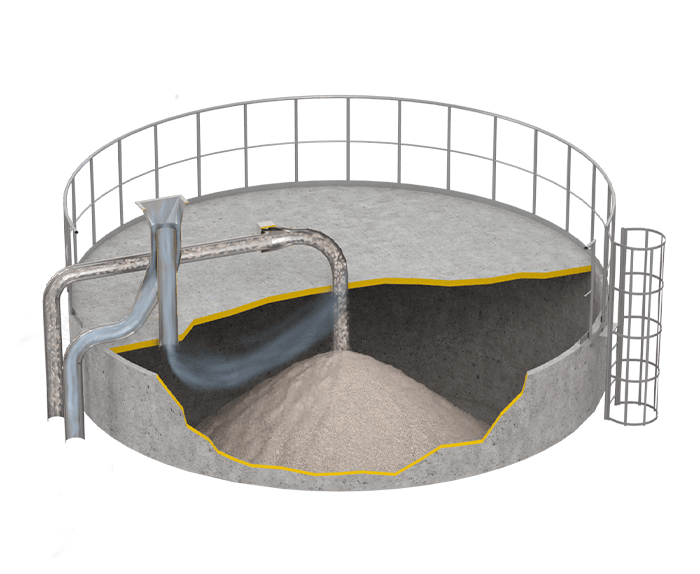

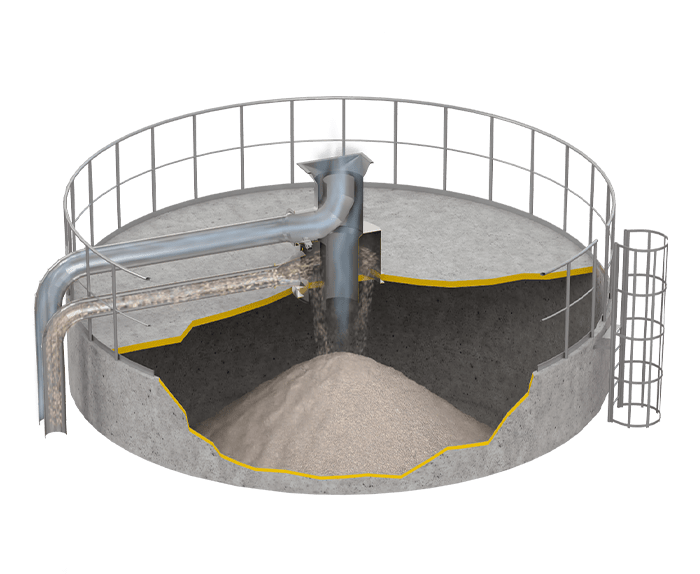

Material separation in the closed circular pipeline system

In this case, a separator is used at the end of the conveying path. Which type of separator should be used will depend on the project-specific requirements. With its comprehensive product portfolio, Scheuch LIGNO provides efficient solutions for every application: