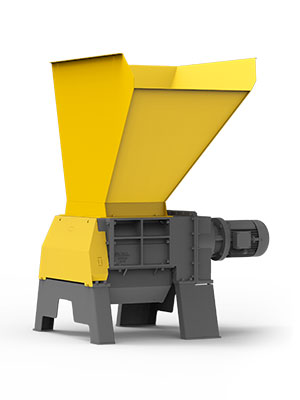

Chippers – shredders

High quality shredder for all applications

Recycling the residual materials and waste materials that occur is becoming increasingly important to owners. Scheuch LIGNO can use precise analyses and requirements analyses to offer and implement a wide range of machines for various applications. Reliable, robust and durable – that’s how a shredder should be.

Scheuch LIGNO’s main focus is on positioning the machine according to requirements in order to optimise the route for disposing of and removing the materials that occur, right up to final storage.

Scheuch LIGNO pays attention to ensuring that high quality machines are used to guarantee durability and readiness for use over a long period.

The Scheuch LIGNO high quality shredder’s numerous designs enable the right solution for any application – suitable for small wood processing companies, joiner’s workshops, carpentry firms and sawmills.

Regardless of whether you are shredding hardwood waste, veneers or other materials such as paper, cardboard or plastic, the reliable shredders guarantee that all residues are shredded efficiently and cost-effectively.

Quality features of our wood shredders

Tried and tested cutting systems

The wood shredder is available in two different cutting system versions:

1-shaft cutting system

The 1-shaft cutting system ensures efficient shredding, long service lives for the indexable inserts and low maintenance costs. Together with the powerful drive train, both with and without slider system, it ensures that the residual material is shredded reliably.

4-shaft cutting system

The tried and tested 4-shaft cutting system is used especially for hard requirements. The cutting discs are not sensitive to impurities, are designed for intensive continuous operation and are particularly cost-effective thanks to the long service life.

Product overview and application options

LR520

Compact and reliable

1-shaft shredding system for small wood processing companies

LR700

Compact and all-purpose

1-shaft shredding system for joiners’ workshops and carpentry companies

RS30/RS40

Reliability for many years

4-shaft shredding system for the woodworking industry

LR630

Low price, high performance

1-shaft shredding system for joiners’ workshops

LR1000/LR1400

Very powerful, for high throughputs

For the woodworking industry

For sawmills