Extraction technology

The ideal solution for extracting dust and chips

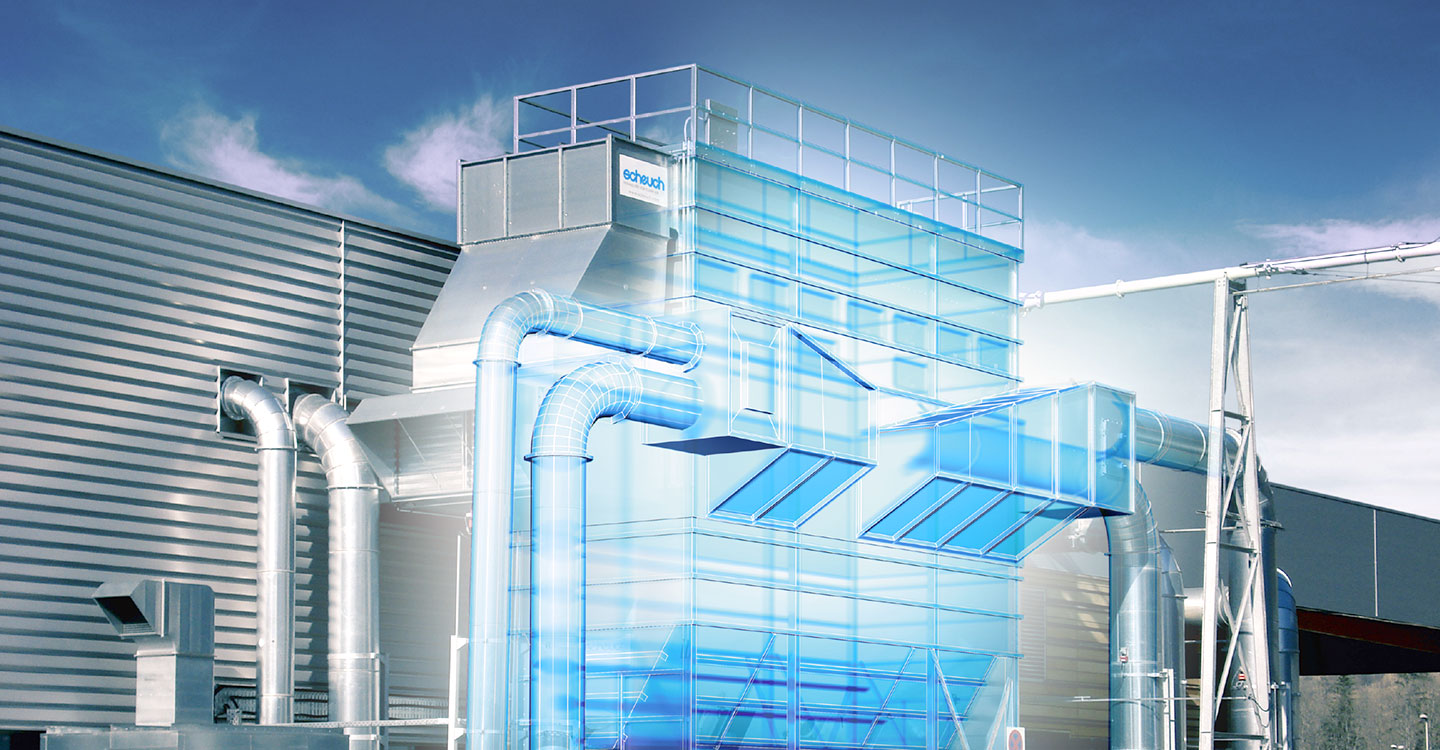

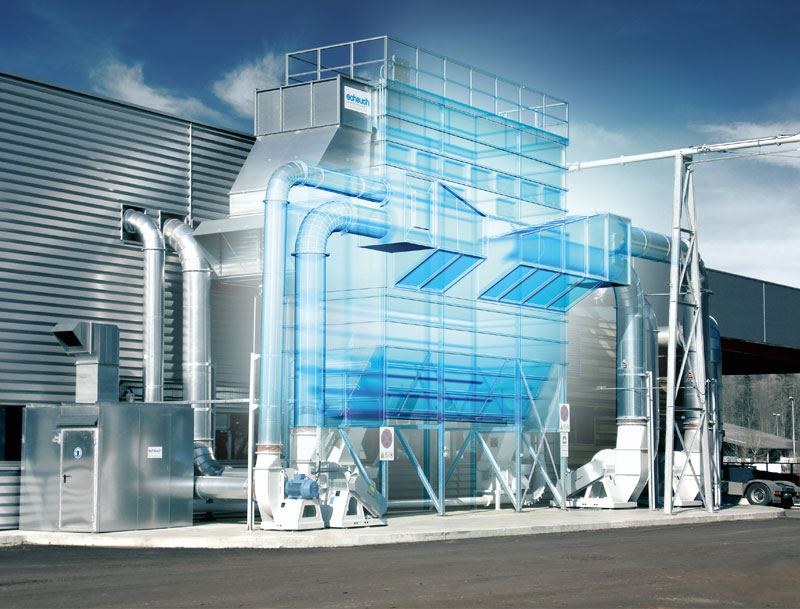

No matter whether it’s excess pressure or negative pressure systems in extraction technology, Scheuch LIGNO takes the best from both technologies for its customers. The key benefit: Scheuch LIGNO masters all technologies thanks to its unique expertise in chip and dust extraction and can therefore always offer perfect and tailored complete solutions. Complete solutions that are also impressive thanks to their cost-effectiveness and energy efficiency.

The Scheuch LIGNO extraction technology is used when processing and machining the widest range of materials. These include

Excess pressure systems

In Scheuch LIGNO excess pressure systems, the fan is in front of the filter. The pressure increase generated by the fan is divided over the filter and the extraction pipework. The filter itself is subjected to excess pressure and must withstand only a relatively small share of the generated pressure. The extraction pipework is subjected to negative pressure and absorbs the majority of the fan pressure. The required pressure increase on the fan can also be defined exactly.

Excess pressure systems in extraction technology are mainly used where extraction takes place on large machines with high power and there are therefore no high capacity differences. However, excess pressures are installed in extraction technology even if there are pipe networks of different lengths, each with different pressure losses.

An example to explain the extraction technology of an excess pressure system:

Numerous changes to a machine fleet require tailor-made solutions. The duct diameters and therefore also the air quantities required to extract the dust and chip materials vary according to the machine. Very different pressure losses may also occur depending on the machine on which extraction takes place and these can have effects on quality and sustainability. In these cases, Scheuch LIGNO relies on excess pressure systems. The fans are installed in front of the filter in the individual ducts and can be tailored precisely to the requirements.

For example, a 100 metre long duct with an inside diameter of 800 at 22 m/s and 40,000 m³/h has a pressure loss of around 480 Pascal while a duct with an inside diameter of 200 at 22 m/s and 2,500 m³/h has a pressure loss of around 2,800 Pascal.

On the excess pressure system, fan 1 can be designed for a 480 Pascal pressure loss and fan 2 for a 2,800 Pascal pressure loss. A suction system (negative pressure system) would have to be designed for the maximum negative pressure that occurs in the system, i.e. for a pressure loss of 2,800 Pascal and the large extraction line would have to be throttled (energy disposed of). On the other hand, the excess pressure system can be tailored to the required pressure increase and is therefore particularly energy efficient.

Negative pressure systems

In negative pressure systems, the fan is integrated into the filter or is downstream of the filter. The filter is subjected to negative pressure, the entire pressure increase is applied to the filter housing. As a filter with a normal panel design only withstands limited negative pressure, this technology is not suitable for all applications. Negative pressure systems are used if the machines have many different capacities, less power is required and the pipelines have very similar pressure losses.

An example to explain the extraction technology of a negative pressure system:

A negative pressure system is used for a machine fleet with the pressure losses in the ducts are virtually identical. This means four processing machines with an extraction connection of around 4,000 m³/h would require an air quantity of around 16,000 m³/h, which could be consolidated into a group extraction system.

On a machine fleet with different machine capacities, consolidation into a combined group extraction system is difficult to achieve, particularly because an air speed of over 16 m/s is required in the combined extraction pipework.

To ensure that the required air speed remains constantly above 16 m/s in the ducts and does not fall below this, individual machines must be switched on to the air permanently so that no material backs up in the ducts. This unnecessary energy consumption can be optimised and counteracted in an energy efficient manner by sepas+, the single pipe system from Scheuch LIGNO. With sepas+, material conveyance in the ducts can be ensured without having to switch the air on unnecessarily in processing machines. Efficient and cost-effective at the same time.

Direct comparison between excess pressure and negative pressure systems

Excess pressure systems |

Negative pressure systems |

|---|---|

| Requirements | |

|

|

| Applications | |

| Solid wood industry (KVH, BSH, BSP), saw mills, planing mills, furniture industry, parquet flooring manufacturers, etc. | Joiners’ workshops, carpenters’ workshops, furniture industry, paper manufacturing, pellet manufacturing, etc. |

| Fans | |

| The fans are very robust and built solidly. Very high material quantities can be conveyed with very long service lives. Decades of fan development enable us to be one of the few companies on the market to also use these in material-loaded areas. | The fans are normally installed directly in the filter. This ensures that the available space is used in an optimum manner. The fans are soundproofed and the waste heat from the motors can also be used. |

| Efficiency | |

| Fans provide short-term, high negative pressures that can compensate for material fluctuations that occur suddenly and therefore enable high system availability. The impellers that are used predominantly have an efficiency of over 80 %. | This is because particularly efficient impellers with an efficiency of more than 85 % can be installed on the clean air side and used. These fans are driven directly. Good access to the fans on the clean gas side is important. |

| Energy efficiency | |

| When regulating the negative pressure on each extraction line, the fans are controlled by frequency converters. The total air quantity in the filter system is regulated. This therefore increases the energy efficiency, keeps the extraction air volumes constant, reduces filter loading to a minimum and therefore optimises the service life of the filter bags. | When regulating the negative pressure on each filter, the fans are controlled by frequency converters. The total air quantity in the filter system is regulated. The connected machines are normally equipped with pneumatic gate valves. Opening and closing the gate valves affects the total air quantity and the negative pressure. A constant negative pressure in the filter system is regulated, whereby only the total air quantity changes. |

| Extraction system | |

|

|

Excess pressure systems

In Scheuch LIGNO excess pressure systems, the fan is in front of the filter. The pressure increase generated by the fan is divided over the filter and the extraction pipework. The filter itself is subjected to excess pressure and must withstand only a relatively small share of the generated pressure. The extraction pipework is subjected to negative pressure and absorbs the majority of the fan pressure. The required pressure increase on the fan can also be defined exactly.

Excess pressure systems in extraction technology are mainly used where extraction takes place on large machines with high power and there are therefore no high capacity differences. However, excess pressures are installed in extraction technology even if there are pipe networks of different lengths, each with different pressure losses.

An example to explain the extraction technology of an excess pressure system:

Numerous changes to a machine fleet require tailor-made solutions. The duct diameters and therefore also the air quantities required to extract the dust and chip materials vary according to the machine. Very different pressure losses may also occur depending on the machine on which extraction takes place and these can have effects on quality and sustainability. In these cases, Scheuch LIGNO relies on excess pressure systems. The fans are installed in front of the filter in the individual ducts and can be tailored precisely to the requirements.

For example, a 100 metre long duct with an inside diameter of 800 at 22 m/s and 40,000 m³/h has a pressure loss of around 480 Pascal while a duct with an inside diameter of 200 at 22 m/s and 2,500 m³/h has a pressure loss of around 2,800 Pascal.

On the excess pressure system, fan 1 can be designed for a 480 Pascal pressure loss and fan 2 for a 2,800 Pascal pressure loss. A suction system (negative pressure system) would have to be designed for the maximum negative pressure that occurs in the system, i.e. for a pressure loss of 2,800 Pascal and the large extraction line would have to be throttled (energy disposed of). On the other hand, the excess pressure system can be tailored to the required pressure increase and is therefore particularly energy efficient.

Negative pressure systems

In negative pressure systems, the fan is integrated into the filter or is downstream of the filter. The filter is subjected to negative pressure, the entire pressure increase is applied to the filter housing. As a filter with a normal panel design only withstands limited negative pressure, this technology is not suitable for all applications. Negative pressure systems are used if the machines have many different capacities, less power is required and the pipelines have very similar pressure losses.

An example to explain the extraction technology of a negative pressure system:

A negative pressure system is used for a machine fleet with the pressure losses in the ducts are virtually identical. This means four processing machines with an extraction connection of around 4,000 m³/h would require an air quantity of around 16,000 m³/h, which could be consolidated into a group extraction system.

On a machine fleet with different machine capacities, consolidation into a combined group extraction system is difficult to achieve, particularly because an air speed of over 16 m/s is required in the combined extraction pipework.

To ensure that the required air speed remains constantly above 16 m/s in the ducts and does not fall below this, individual machines must be switched on to the air permanently so that no material backs up in the ducts. This unnecessary energy consumption can be optimised and counteracted in an energy efficient manner by sepas+, the single pipe system from Scheuch LIGNO. With sepas+, material conveyance in the ducts can be ensured without having to switch the air on unnecessarily in processing machines. Efficient and cost-effective at the same time.

Your customized solution is just one step away!

With our extensive experience, we are your reliable partner for extraction and surface technologies in industry and trade. Guided by our commitment to providing „the most economical solution for trade and industry,“ we work together to achieve the best results tailored to your needs. Simply enter your contact details, and we’ll get back to you as soon as possible.