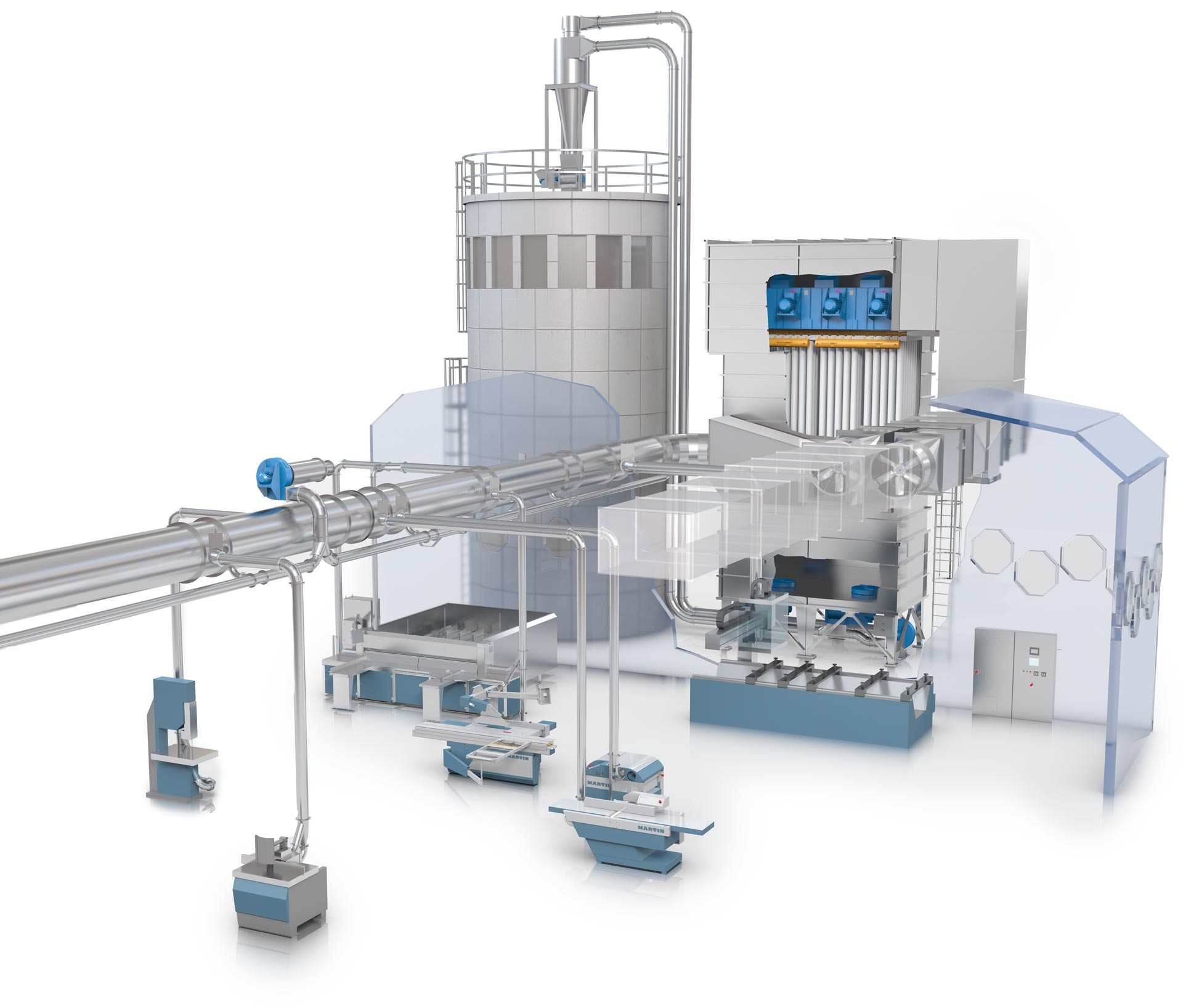

sepas+ negative pressure system

Low energy consumption through flexible extraction

The sepas+ chip extraction system offers a performance range of 9,000 m³/h and above, and its highly efficient use of energy makes it an outstanding choice. The sepas+ system enables the extraction output to be adapted to the fluctuating machine capacity and is therefore particularly energy-efficient.

Activation air system from Scheuch LIGNO

The sepas+ system is characterised technically by a single pipe system with activation for dust and chips. This activation air system invented by Scheuch enables the air velocity in the main extraction pipe to fall below the minimum level at low capacity.

Operational safety is our highest priority at scheuch ligno

In terms of fire and explosion protection, the entire range of dedusting and material conveying systems is ATEX-certified, from collection at the production machine right up to introduction into the silo. This provides legal security for the owner in terms of risk evaluation, and enables determination and limitation of safety zones within explosion protection documents. ATEX-certification, H3 and GS symbols guarantee operational safety and high availability of the extraction system.

Key advantages of sepas+ include higher productivity thanks to the flexibility of the extraction system, low-cost production due to the low energy consumption and excellent operational safety. Furthermore, savings can be made to heating costs, as only the air volume required is extracted.

sepas+ benefits at a glance

Brochure

sepas8000 negative pressure system

The same benefits for smaller performance ranges in extraction technology

Sepas8000 has been designed especially for smaller companies with lower air quantities. The sepas8000 negative pressure system offers a performance range of up to 10,000 m³/h, and its highly efficient use of energy makes it an outstanding choice. Sepas8000 enables the extraction output to be adapted to the fluctuating machine capacity and is therefore particularly energy-efficient. The Scheuch ligno DeDustpro deduster is used with sepas8000.

References

Sepas is also used for insulation plate production.