Filter Technology

When it comes to filters, Scheuch LIGNO’s extensive expertise in filtration and dedusting technology comes into its own – particularly in terms of energy saving and fire and explosion protection.

Scheuch ligno filter with impulse cleaning

Efficient & operationally safe

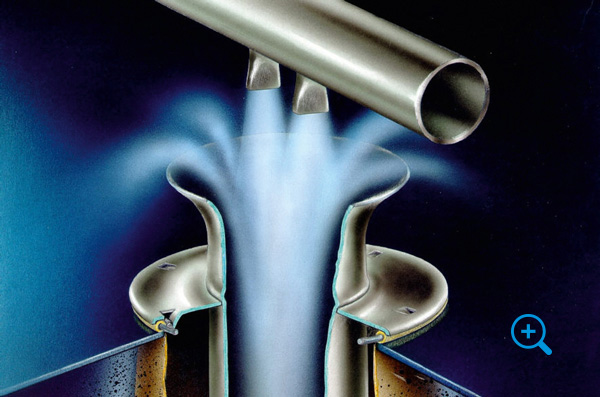

The impulse cleaning system developed by Scheuch is highly efficient and energy-saving. With a high proportion of secondary air, the specially-shaped twin nozzles ensure efficient and extremely gentle cleaning. This results in lower consumption of compressed air, longer cleaning cycles and therefore a longer bag service life.

Compressed air costs for cleaning in €/shift per year*

*at 1920 h/year, 12 cent/kWh

Energy requirement – highly efficient filter cleaning

The Scheuch injector ensures reliable cleaning and low energy costs.

The Scheuch LIGNO impulse cleaning system must be considered both in terms of energy efficiency as well as operational safety. In order to minimise operating costs for an extraction and dedusting system, the correct choice of system design as well as optimised sizing and planning of the pipework is decisive. The interaction of efficient individual components and an effective system design enables the best solution – both technically and economically.

The low filter system pressure loss thanks to the Scheuch LIGNO impulse cleaning system has a great deal of influence on the potential energy savings. 10 % less resistance means 10 % less energy required. The integral fans (EtaMax unit) on the EtaMax filter systems also enable further energy savings and increase the efficiency.

Low operating costs for the filter system

The filters have been optimised according to flow engineering criteria.

In addition to efficient cleaning, the pressure loss in the filter system itself and the filter bag is especially crucial to the operating cost. With the development of the series, the filter casing has been flow-optimised using CFD simulations.

The ligno01 filter bag developed by Scheuch LIGNO guarantees a very low filter resistance over a long lifetime as a result of the surface-oriented filtration behaviour of the dust penetration being so low and so maintaining the air permeability.

The baffle plates in the crude gas inlet ensure pre-separation of the volume primarily made up of chips and dust residue, and generate a cross-flow through the dust collection container. This prevents previously separated chips and dust swirling up. The TOP-DOWN effect supports the downward movement of the cleaned dust particles for discharge.

Low noise emissions with scheuch ligno filters

Different, standardised soundproofing packages

Various standardised soundproofing measures are available depending on whether the systems are installed in industrial estates, in mixed construction areas or even for night operation. This guarantees that Scheuch LIGNO filters do not just comply with noise guidelines but normally fall way below them. For more information, see › Soundproofing.

Scheuch ligno filter for universal use

The finely stepped series and flexible modular system satisfies all demands, in terms of construction size, height and shape, with a range of different discharge versions already incorporated into the standard range and hence good value without additional time invested.

Scheuch ligno filters for versatile uses

For wood, metal and other materials

The ligno filters are versatile for use in processing industries. In addition to wood and metal chips, other materials such as paper, cardboard, rubber and plastic, insulation materials, compound materials, leather or textiles can be extracted without problems. The ligno filters are designed so that they can be used individually according to the customer’s requirements.

Your customized solution is just one step away!

With our extensive experience, we are your reliable partner for extraction and surface technologies in industry and trade. Guided by our commitment to providing „the most economical solution for trade and industry,“ we work together to achieve the best results tailored to your needs. Simply enter your contact details, and we’ll get back to you as soon as possible.