SCHEUCH lignoEP briquetting press

Briquetting presses for wood dust and related materials

Briquetting systems make it possible to dispose of the dust and chips created during filtration in a way that is cost-effective and saves space. Briquetting can be used for low-dust storage, recycling or disposal of these materials. The space requirements for storage are reduced greatly by briquetting.

The Scheuch LIGNO briquetting press is a fully automatic machine for pressing dust and chips from cellulosic materials or similar, such as wood, paper or plastic, into briquettes. This can either be attached directly to a filter system or designed as a standalone system with its own chip container.

Operation takes place via a 7-inch touch panel that provides the operator with numerous adjustment options. The briquetting press works fully automatically following a request from a filter system or via the fill level sensor’s signal. The presses are tested according to GS-HO-01, have the GS mark and are designed for temperature-controlled indoor spaces.

Advantages at a glance:

Brochure

Function

The material stored in a chip container is conveyed into the tamping shaft via an agitator and the feed screw. The tamping cylinder compresses the inserted material into the pressing chamber. In this, the press cylinder compresses the pre-compressed material into a briquette by pressing it against the briquette produced in the previous cycle in the briquette tube. At the end of the compression process, the plier cylinder opens briefly to push the briquette produced into the briquette tube. The cycle then starts again from the beginning.

As a rule, there is a silo intermediate container above the press, often with a filter system placed above it. These chip containers provide a certain buffer volume, as the press can only briquette the fed material continuously according to the available pressing capacity until it is emptied.

Discharge arm with stuffing screw

Mechanical system

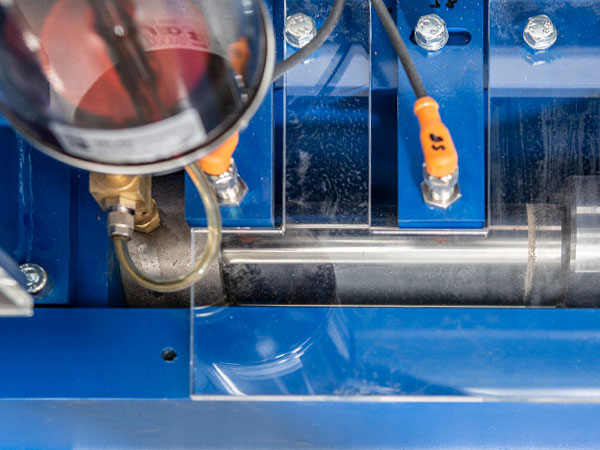

Oiler and sensors on the press cylinder

Controller

Versions

| Type | EP/SP 50 |

|---|---|

| Drive | 4.0 KW |

| Press output | 30–50 KG/h |

| Press output for chips | bis 200 m³/year |

| Briquette diameter | 60 mm |

| Type | EP/SP 70 |

|---|---|

| Drive | 5,5 KW |

| Press output | 50–70 KG/h |

| Press output chips | bis 300 m³/Year |

| Briquette diameter | 60 mm |

| Type | EP/SP 90 |

|---|---|

| Drive | 7,5 KW |

| Press output | 60–90 KG/h |

| Press output chips | bis 500 m³/Year |

| Briquette diameter | 60 mm |